As the semiconductor and electronics industries demand ever-greater precision and complexity, the role of inspection and metrology becomes mission-critical. Marposs Group, a global leader in measurement and control technology, is rapidly expanding its presence in the semiconductor and consumer electronics sectors. With innovative, high-precision solutions tailored for wafer processing and micro-component inspection, Marposs is redefining quality control in one of the world’s most demanding industries.

Innovative Solutions Powering Precision

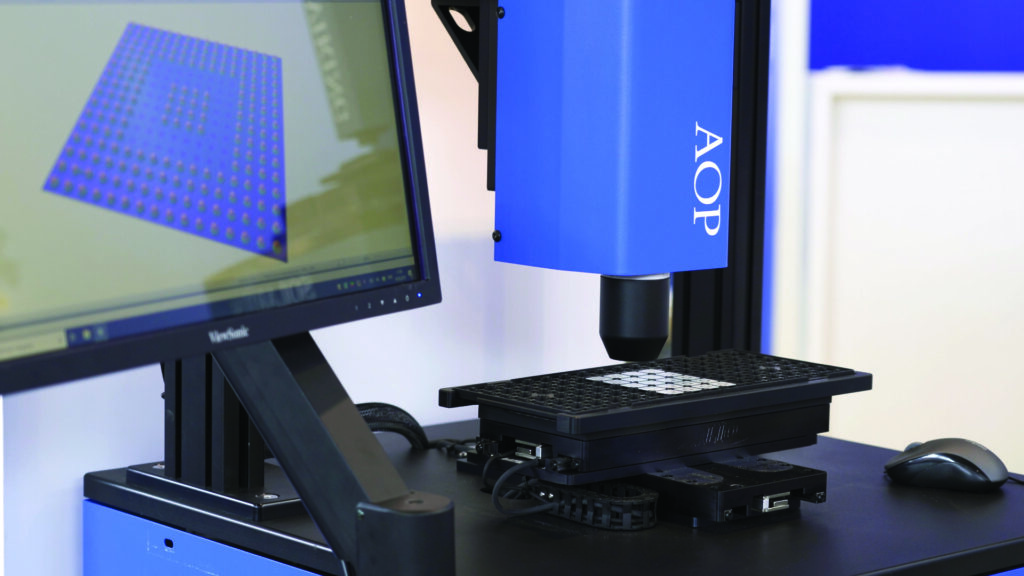

1. Phoenix Desktop 3D by Solarius (a Marposs Company)

Following the acquisition of Solarius Development Inc., Marposs introduced the Phoenix Desktop 3D surface measurement system, designed for ultra-precise surface inspection. Powered by chromatic confocal technology, Phoenix delivers sub-micrometric accuracy, nanometric axial resolution, and automation-friendly X/Y movement—ideal for semiconductors, 3C products, medical, and aerospace applications.

2. NCG Thin Line Interferometric Gauging

The NCG system uses advanced interferometry to measure the thickness of single or multilayer materials like silicon, sapphire, glass, or GaN. Equipped with infrared sources, it can inspect even non-transparent materials. Its robust software ensures accuracy even in optically noisy environments—essential for harsh shop-floor conditions.

3. P3CF + Unimar Hybrid System

This hybrid solution merges confocal sensing with touch probe technology. Perfect for indirect thickness measurement, P3CF captures the distance of the top surface without contact, while Unimar contact probes measure the reference base, enabling precise differential thickness readings even when materials resist infrared penetration.

Smart Factory Integration

All Marposs systems are engineered for Industry 4.0 compatibility, offering seamless data sharing via Fieldbus and custom software protocols. From offline inspections to fully automated production lines, Marposs tools ensure real-time feedback, error reduction, and superior quality control.

Looking Ahead

As device architectures become more intricate and wafer materials evolve, Marposs continues to invest in intelligent metrology that keeps pace with tomorrow’s manufacturing needs.